Why those bottles exploded in Agent Hank Schrader's garage

Warning: Breaking Bad spoilers below. But, really, shame on you if they're still spoilers.

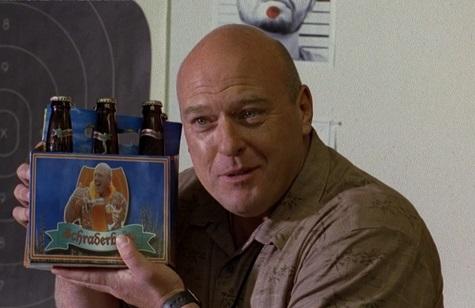

When Uncle Jack pulled the trigger, ending Hank Schrader's life, Breaking Bad fans' hearts turned a grade of blue that even Heisenberg couldn't synthesize in his lab. At that moment, though, out in the middle of New Mexico's dry, hot desert, we couldn't help but think Hank was wishing for just one last pint of Schraderbraü before the end.

That's right, in case you forgot, in addition to being a federal agent, he was an avid homebrewer, with a whole setup in his garage devoted to the hobby. And like any homebrewer, he was damn proud of it, too.

Recall him saying, “Alright, some of you already know my brother-in-law. He’s a good man. The doctors are saying this operation has a real chance of helping him. Of course they’re also saying they want to be paid in private islands, so dig deep. Biggest donation gets a six-pack of my very own Schraderbraü. Homebrewed to silky perfection.”

But as most homebrewers know, that silky perfection doesn’t come without a bit of trial and error. Hank experienced this first hand when he over-carbonated his brews, causing a string of exploding bottles in his mancave. In this post, we’ll discuss why that happened and how you can avoid it.

What kind of Beer was Schraderbraü anyway?

Before getting into Hank's bottle bomb issues, let’s first set the stage by discussing which type of beer Schraderbraü actually was. This is a hard one, since he never describes it to anyone and the label simply states “Schraderbraü.” But there is one thing that tipped us off. It was the song he sang: “Here’s to good friends/Tonight is kind of special..."

A quick Google investigation matches those lines to this 1978 Löwenbräu commercial:

We’ll speculate on the similarities between the name and theme song as well as the beer’s light color to say Schraderbraü’s in fact a pilsner.

So, why did the bottles explode?

To understand the source of the exploding bottles, we have to first understand fermentation, or the process of yeast breaking down sugars. During this process, 2 by-products are produced: ethyl alcohol and carbon dioxide (CO2). During your brew, after boiling the sugary wort and cooling it, yeast is added and this process begins. The excess CO2 is released by way of an airlock, so no pressure is generated.

However, when fermentation is complete and it’s time to carbonate, the brewer adds additional sugar (this is called priming sugar) for the yeast to “feed” on. The difference between adding sugar earlier in the brewing process and during bottling is the airtight cap attached to each bottle rather than an airlock. The cap prevents CO2 from escaping, and as CO2 pressure builds inside the vessel, it begins to dissolve into the liquid—voila—you have carbonation.

Now, this process isn't always executed correctly, and sometimes outside factors play a role, causing over-cabonation. In this case, you run the risk of having a few bottle bombs on your hands. When the tops start popping off, it's disappointing, messy, and—if you're Hank Schrader—can be mistaken for incoming cartel gunfire.

How do you avoid over-carbonation?

1. Start by using your hydrometer: If you're brewing in a hurry (or if you're drinking while brewing) it's easy to forget to measure the original gravity (OG) before pitching your yeast. Measuring specific gravity (or a liquid's density relative to water) is not only a best practice, but comparing your recipe's target readings to your specific brew will help tell if fermentation is complete.

2. Make sure your yeast is alive and kicking: In addition to measuring your beer's specific gravity, be sure that the temperature of your beer is within your yeast's target range. If you're skeptical that the yeast has finished it's job, a good test is moving your beer to a slightly warmer area. If fermentation picks back up, the yeast may have simply become dormant. We brewed a batch during a particularly cold stretch this winter—and even with the heat on, we noticed an ebb and flow of yeast activity depending on the ambient temperature in the room. If you're ever in doubt and don't have a gravity reading to go by, raising the temperature slightly and waiting are both safe plays to avoid accidental over-carbonation.

3. Take care to measure your priming sugar: There are lots of sugars which can be used to give your yeast the "kick" it needs to carbonate your beer, but sometimes it's difficult to know exactly how much to add. Northern Brewer has a great priming sugar calculator available here to make sure you use the right amount of sugar, no matter the type!